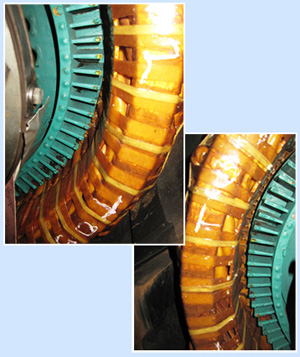

The build-up of oil and dirt on the surface of the insulation creates increased temperature and decreased efficiency and insulation values.

Cleaning with chemicals removes oil and dirt from sight, but it does not remove it from the generator.

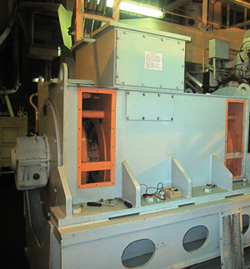

The Solution is the GENTEK MARINE In-Situ Generator Cleaning System

- An optimal solution without using any fast evaporating solvents

- Requires no dismantling of rotor or extracting of any components

- Qualified engineers will do the cleaning services

- Insulation tests are carried out in cooperation with shipboard personnel

- Oily and dirty areas are saturated with water-based degreaser soap

- The soap is washed off with filtered and deionized hot water (70/85 0C)

- Insulation is restored by drying/baking the generator with large volume of warm air (95/100 0C)

- Portable heating system is provided

Apart from In-Situ Generator cleaning GENTEK also provides other Marine Services:

- In Place Generator Cleaning

- Refrigeration and HVAC installations/ repair/ services

- Gas conversion

- Safety relief valves services

- Commissioning of electrical system

- Insulation test of electrical system

- Thermo-graphic inspection of switchgear to bus-bar

- Calibration / certification and testing

- Main and auxiliary engine lube oil pressure shut down

- Repair and reconditioning of marine products

Mud motor cleaning and varnishing

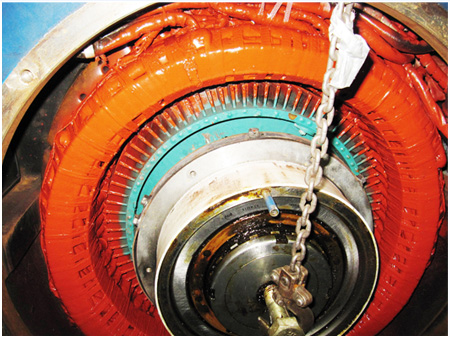

Before cleaning:

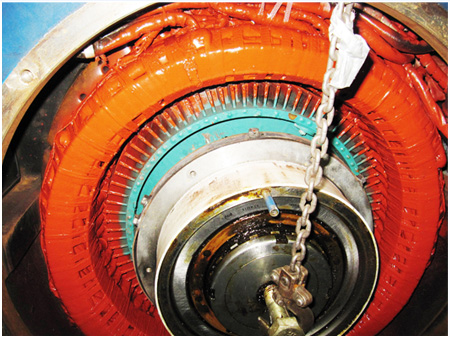

After cleaning, before varnishing:

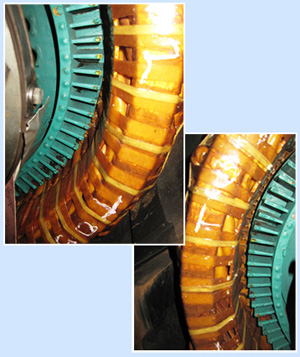

After varnishing: